Typhoon is the first student developed liquid rocket engine at Iowa State University. It is a pressure-fed, regeneratively cooled, and open cycle rocket engine.

*Model is currently being updated, renders coming soon*

- Thrust = 2668.93 N ~ 600 lbf

- Kerosene (Rp-1) & lOX – ISP (Sea Level) = 269 sec

- Pc = 3.1026e6 Pa ~450 psi or 30.6 atm

- Tc ~ 3450 K

- Me = 2.79

- Ae/A* = 4.63

- Ac/A* = 10.72

- C* = 1778 m/s -> 98.5 % Theoretical C* Efficiency

- O/F = 2.22

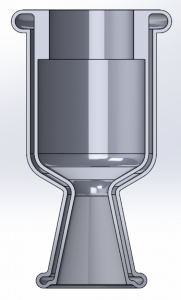

Regenerative Cooling System

The regenerative cooling system will allow us to theoretically increase the specific impulse during theoretical combustion by about 1-5%. The regenerative cooling system operates by cycling the “fuel” axially across the thrust chamber, by adding heat to the “fuel”, we are effectively improving engine performance and maintaining the temperature of the material to prevent creep.

Depiction of Regenerative Cooling Chambers

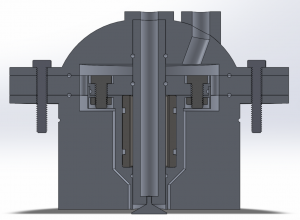

Pintle Injector

What is the purpose of an injector?

The purpose of an injector is to atomize the propellant streams in the combustion chamber by injecting the propellants at high velocities and pressures. These impinging streams are the fuel and oxidizer. The Pintle Injector is designed to carry fluid from both intakes and allow the fluid to vaporize within the thrust chamber. The atomization of fluid within the thrust chamber allows us to improve our theoretical combustion efficiency which allows us to compensate by reducing chamber length and overall reducing the weight of Typhoon 1.0.

Why is a Pintle Injector advantageous apart from other types of injectors?

- Throttle Capability

- Has consistent high performance over a wide thrust range

- Simplicity allows for cost and weight savings

- Protection against combustion instability

Current Design of Pintle Injector