Developing Next Generation Space Construction Technologies

Space Construction Technologies, SPACECO, is founded in January 2021 by 11-researcher in order to develop next generation space construction technologies. As a result of brainstorming for wide range of space technology ideas, basic principles of cold welding technique has been observed. In March 2021, SPACECO has submitted a proposal and new technology report (NTR) for Removable Coating for Cold Welding (RECO) technology under L'SPACE program to NASA. The proposal has been approved by the NASA Center Chief Technologist and SPACECO has received a funding by NASA in April 2021. Along with that, NASA Technology Transfer Program has listed RECO technology as a new invention in their NTR system. With the beginning of Fall 2021, SPACECO has partnered with Make to Innovate program of Aerospace Engineering Department at Iowa State University to start laboratory research. Currently, SPACECO consists 14-researcher and two Subject Matter Experts who are welding engineer/metallurgist at NASA MSFC.

Team and Project Organization Chart

Dr. Jeffrey Sowards

sme

Zachary Courtright

sme

Sheri Boonstra

advisor

Peter Stokes

advisor

Mehmet B. Sefer

PROJECT MANAGER

Mitchell Strobbe

d. project manager

Onur Onal

LAB RESEARCHER

Selim Erenay

LAB RESEARCHER

Ahmet Emre Okur

LAB RESEARCHER

Project Mission Statement

Due to the increased capability of both government agencies and private companies, space missions have become far more complex. Many of these missions involve building large structures, such as the Lunar Gateway, large satellites, or what is necessary for Moon/Mars habitation. These structures are too large to be launched as a single payload, requiring in-space construction. The ability to weld these structures together while in space would allow for strong, airtight seals and easy construction of many new structures. SPACECO aims to research and invent a technology, Removable Coating for Cold Welding (RECO), to enable cold welding in space applications.

Project Goals

1- Write Sample Preparation Procedures

2- Design, Assemble, and Test High Vacuum System

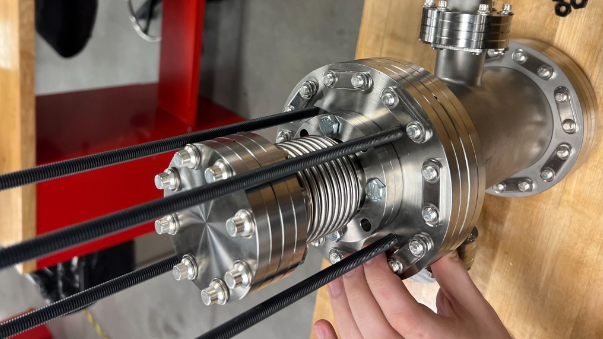

3- Manufacture Linear Motion Enabled High Vacuum Adapter

4- Test Cold-Welding within High Vacuum Setup

Project Deliverables

Our major deliverables for this semester are writing sample polishing procedures, designing and assembling a high-vacuum system, and cold-welding experiment test results. The minor deliverables include the tasks that were not fully completed last semester: finalizing and testing the hydraulic and glovebox systems.

Major Milestones

February 24 – Writing Sample Preparation Procedures

March 3 – Hydraulic System Verification & Validation

March 10 – Glovebox and High Vacuum Validation & Verification

May 5 – Cold-Welding Test Results

Progress Made

We worked on custom-built tools and systems necessary for the RECO technology and cold-welding experiments this semester. We wrote guidelines for sample preparation procedures. The high vacuum system is designed and assembled by our team members. The high vacuum parts are modified to integrate the linear motion-enabled high vacuum adapter we machined. With this adapter, the force can be transferred into the high vacuum without any leaks. Finally, we conducted two successful cold-welding experiments.

Project Reflection

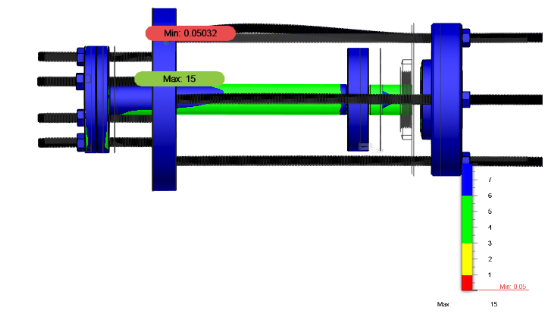

- Designing and manufacturing a linear motion-enabled high vacuum adapter was the most challenging goal. Because the off-the-shelf linear motion adapters for the high vacuum systems are designed for high-pressure applications such as 40 kN, we had to design and manufacture our own system. Several finite element analyses (FEA) are conducted for different failure scenarios until the FEA validates that the system is safe to operate under all conditions. The manufacturing process is done on our own with a milling machine and horizontal band saw at the SIC metal shop.

- Another challenge we faced this semester was finding a way for sample mounting. Because our test samples are very thin, it’s not possible to hold them on the polishing wheel. The standard mounting methods such as epoxy and acrylic were not suitable for our experiments because we needed to remove the sample from the mount without causing any bend or twist after the polishing process. Our solution to this challenge was to use CrystalBond. We mix this mounting adhesive with acetone and apply it to the back surface of the samples to mount them to the circular aluminum blocks by applying heat at the same time. The samples can be easily removed by re-heating the aluminum mounts.

- The next semester, we will integrate Ion Pump, Ion Pump Controller, and UHV Valve into our existing high vacuum system to upgrade it to ultra-high vacuum. After this, the team will focus on conducting cold-welding experiments throughout the semester.

For any inquiries, please email info@spacecotech.com 2023 | Space Construction Technologies | All Rights Reserved